Mig welding, also known as Gas Metal Arc Welding (GMAW), is a popular welding process that is commonly used for joining thin sheet metal. It is known for its versatility and ability to produce high-quality welds in a variety of materials, making it an ideal choice for many applications.

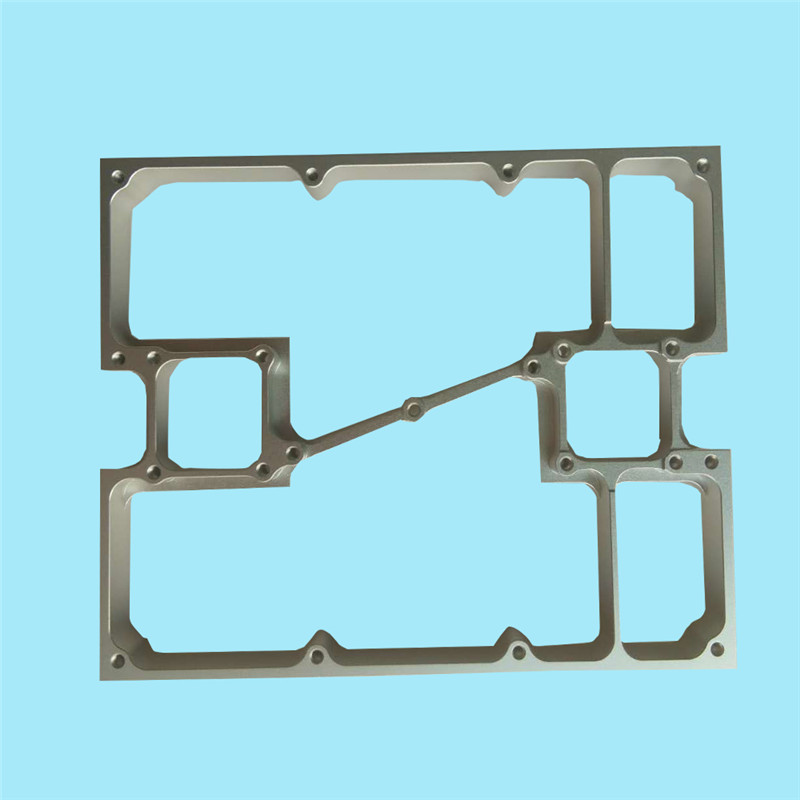

The addition of Mig Welding Sheet Metal to LongPan's list of services will allow the company to offer a more comprehensive range of solutions to its customers. With the ability to both machine and weld sheet metal, LongPan will be able to provide a one-stop shop for the production of high precision parts.

"We are very excited to announce the addition of Mig Welding Sheet Metal to our list of services," said a spokesperson for LongPan. "This new capability will allow us to better serve our customers and provide them with a complete solution for their manufacturing needs."

In addition to Mig Welding Sheet Metal, LongPan also offers a range of other services, including CNC machining, turning, milling, and assembly. The company's state-of-the-art facility is equipped with the latest technology and machinery, allowing it to consistently produce parts with very tight tolerances and high precision.

LongPan's dedication to quality and customer satisfaction has made it a trusted partner for many leading companies in the automotive, medical, railway, and other industries. With the addition of Mig Welding Sheet Metal, the company is well-positioned to further strengthen its reputation as a reliable and innovative manufacturer.

The demand for high precision components in industries such as automotive, medical, and railway is constantly growing, and LongPan is committed to meeting this demand with its expanded capabilities. Mig Welding Sheet Metal will enable the company to produce complex and intricate parts with ease, further solidifying its position as a leader in the manufacturing industry.

LongPan's team of highly skilled engineers and technicians are experts in their field, and they are prepared to take on the most challenging projects. With a focus on continuous improvement and innovation, the company is constantly striving to exceed customer expectations and deliver superior results.

"We are confident that the addition of Mig Welding Sheet Metal will open up new opportunities for us and allow us to better serve our customers," said the spokesperson. "We are committed to staying at the forefront of technology and providing the best possible solutions for our clients."

As LongPan continues to grow and expand its capabilities, the company remains dedicated to maintaining its high standards of quality and excellence. With a focus on precision and attention to detail, LongPan is well-equipped to meet the evolving needs of its customers and the industries it serves.

In conclusion, the addition of Mig Welding Sheet Metal to LongPan's list of services represents a significant milestone for the company. With its commitment to innovation and excellence, LongPan is poised to continue its success and remain a leader in the manufacturing industry for years to come.