One of the most popular materials for laser cutting is aluminum. The lightweight and durable nature of the metal make it ideal for a variety of applications, from aerospace components to consumer electronics. Aluminum is also highly moldable and resistant to corrosion, making it a great material for use in industries that require precision and consistency.

Aluminum molds are especially popular for casting, a process that involves pouring molten metal into a mold to create a specific shape. These molds can be highly intricate and precise, and require a tool that can make accurate cuts to ensure the quality of the final product.

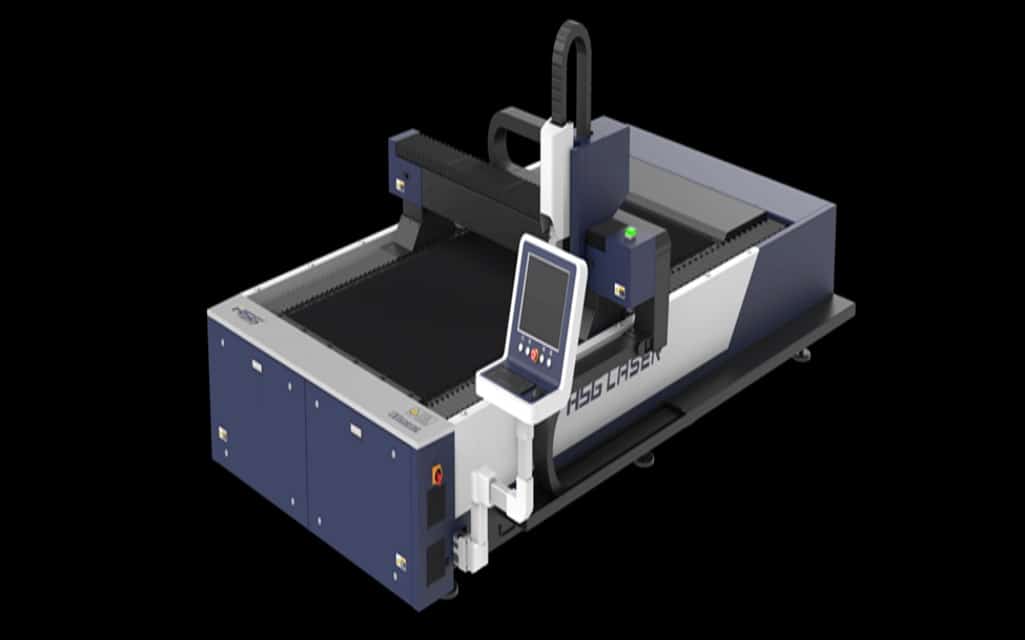

That's where sheet metal laser cutting machines come in. With a laser cutting machine, manufacturers can create highly precise aluminum molds that can withstand the rigors of the casting process. These molds can be used to create a wide range of products, from car parts to custom jewelry.

One of the most significant benefits of using a sheet metal laser cutting machine for aluminum mold casting is accuracy. The laser beam can make extremely precise cuts, which is especially important when creating intricate molds with highly specific designs. With a laser cutter, manufacturers can create molds with tolerances as small as a few thousandths of an inch.

Another important advantage of using a laser cutter for aluminum mold casting is speed. Because laser cutters work quickly and efficiently, manufacturers can produce molds much faster than they would using traditional cutting methods. The enhanced throughput of these machines also means that manufacturers can produce more molds in less time, increasing overall productivity.

Sheet metal laser cutting machines for aluminum mold casting also come with fully enclosable interchangeable tables. This feature provides operators with ease and enhanced throughput. The operator does not need to manually swap out tables to continue their work. The moving mechanism allows for a smooth transition between tables.

Finally, sheet metal laser cutting machines for aluminum mold casting are highly versatile. They can work with a wide range of materials, including aluminum alloys, and can be used to create molds with varying thicknesses and shapes.

In conclusion, sheet metal laser cutting machines for aluminum mold casting are a game-changer in the manufacturing industry. They offer precision, speed, and versatility, allowing manufacturers to create highly accurate molds with ease. With the ability to produce molds quickly and efficiently, companies can increase their productivity and profitability, while delivering high-quality products to their customers.