In today's world, manufacturing companies across the globe are constantly in search of new ways to increase efficiency and streamline their processes. The traditional methods of cutting, shaping, and engraving materials have been around for a long time and have served as the backbone of manufacturing processes for years. However, technological advancements have led to the development of more advanced cutting and engraving techniques such as steel laser cutting, which has rapidly gained popularity in recent years.

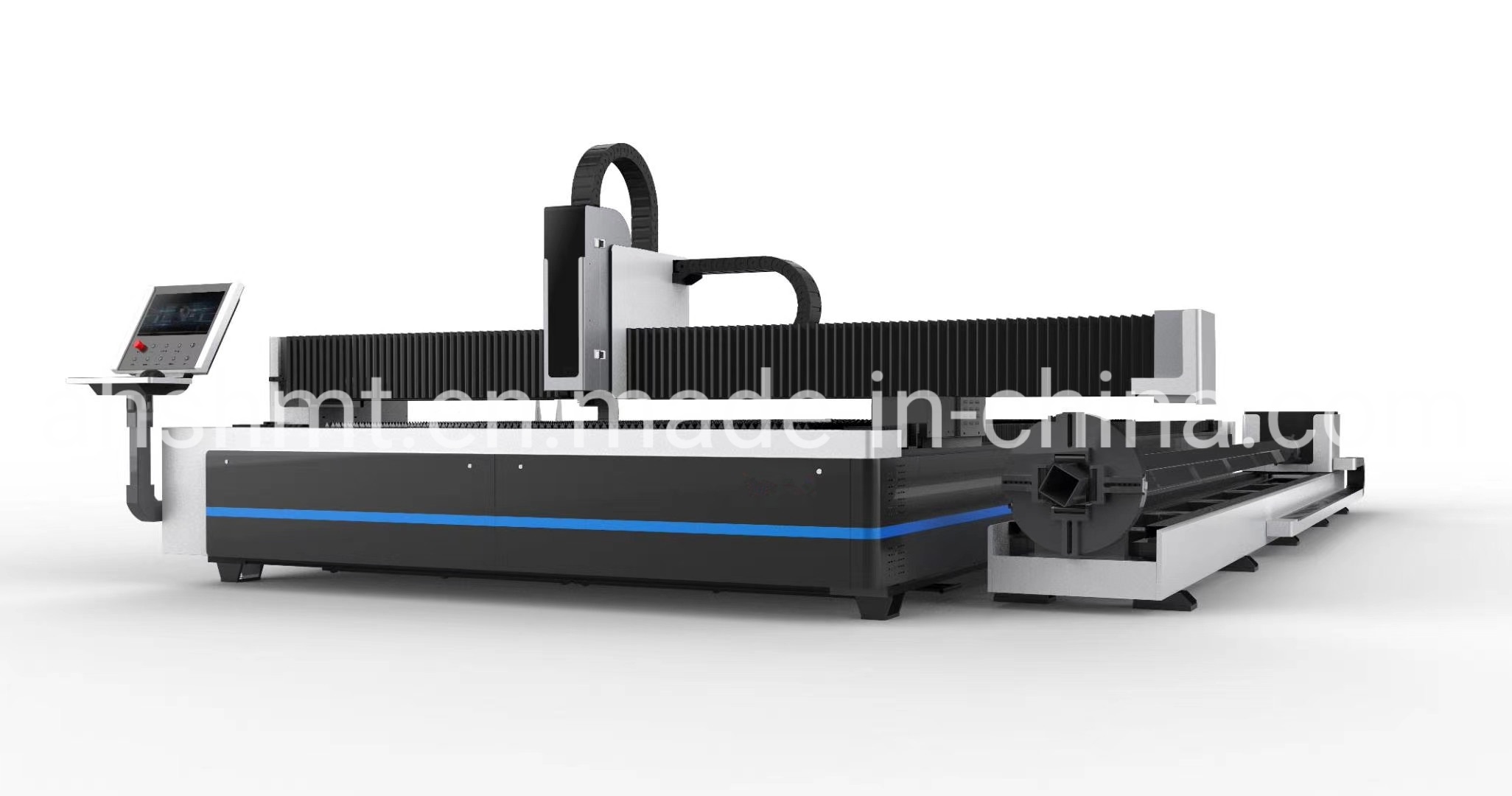

Steel laser cutting is a process that uses a laser beam to cut through or engrave various metals, including stainless steel, aluminum, and brass, among others. This advanced technology is known for its precision, accuracy, and clean edges, making it ideal for manufacturing parts and components with intricate designs, shapes, and finishes.

One of the primary benefits of steel laser cutting is that it helps to reduce material waste as it enables designers and engineers to create parts with minimal tolerance levels. This technique also tends to be faster than other traditional cutting methods, meaning that it helps to speed up manufacturing processes.

Why consider using Laser cutting?

Speed

Laser cutting is quicker and more precise than traditional cutting techniques. Once the laser machine is set up and ready to go, the process can be completed in seconds, allowing manufacturers to work faster, produce more parts, and increase their overall output.

Precision

Steel laser cutting is incredibly accurate, as the laser beam follows the design specifications programmed into the machine. The beam burns the metal, forming clean, accurate cuts that are free from burrs and other rough edges.

Material applications

The laser technique is much more effective for cutting a wider variety of materials than traditional cutting methods can cover. It can be used to cut plastics, papers, and textiles, as well as metals with low melting points like aluminum and copper.

Versatility

Steel laser cutting is versatile, allowing designers to create almost any shape or design they desire, quickly and easily. With the right software, they can cut out intricate designs and shapes that they could never create using traditional CNC machining or manual cutting methods.

Reduced Labour Costs

Laser cutting machines can be more expensive than traditional cutting machines. However, the increased speed and accuracy of laser cutting processes means that the manufacturer can save a considerable amount on labor costs, cutting the cost per part.

Cleanliness and Finished Product

The cleanliness of Laser cutting is one of its biggest advantages. The laser cuts cleanly and efficiently, ensuring that finished parts and components look great, feel good to the touch, and work effectively.

Final thoughts

Steel laser cutting is fast replacing traditional cutting methods in manufacturing industries. With precision, speed, versatility, and a clean finish, this advanced technology is transforming how manufacturers create their products. As the technology continues to evolve, the cost of laser cutting systems is expected to keep falling, making it even more accessible to businesses of all sizes. For now, businesses seeking to streamline their manufacturing processes should consider steel laser cutting technology for fast, accurate, and high-quality results.