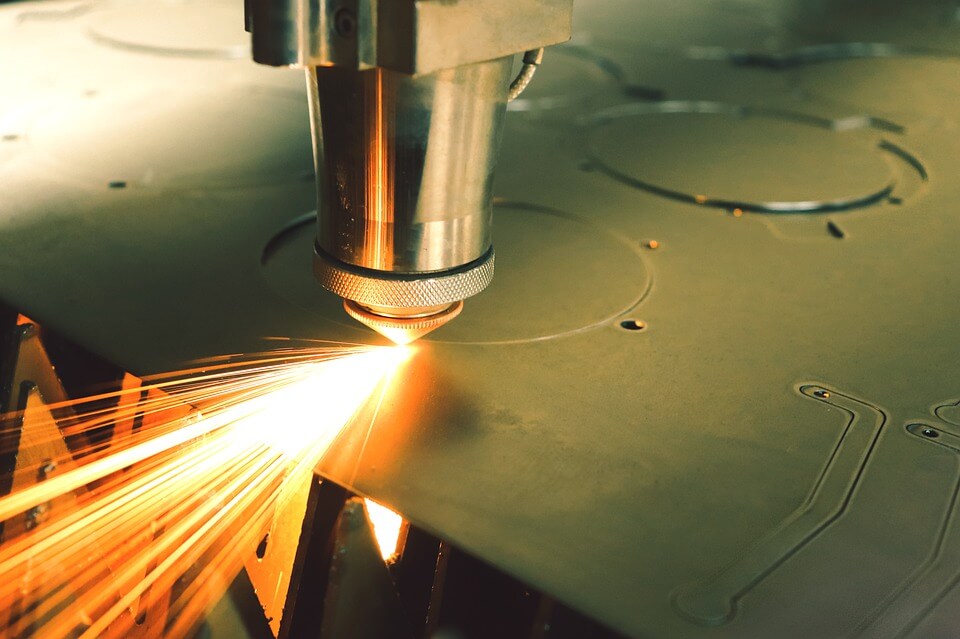

One of the main advantages of laser beam cutting is the ability to achieve tight tolerances and high-quality edge finishes. The laser beam itself is incredibly precise, which means that even the most complex shapes and geometries can be achieved with ease. Unlike traditional cutting tools, which can cause distortion and warping, the laser beam exerts no force, which means that the material retains its original shape from start to finish.

Another advantage of laser beam cutting is its flexibility. The process can be tailored to suit a wide range of applications, from cutting thin materials with high accuracy to cutting thick materials at high speed. This means that manufacturers can create a wide range of products with a single process, saving time and reducing costs.

In addition to its precision and flexibility, laser beam cutting is also a cost-effective process with low operating and maintenance costs. This is because the process is automated, which means that there is no need for manual intervention or tool changes. The laser beam also has a long lifespan, which means that it can be used for thousands of hours before needing to be replaced.

Laser beam cutting has a wide range of applications across various industries. In the automotive industry, it is used for cutting car body panels, while in the aerospace industry, it is used for cutting turbine blades and other components. It is also used in the medical industry for cutting surgical instruments and implants, as well as for cutting intricate patterns in textiles and leather goods.

In conclusion, laser beam cutting is a versatile and cost-effective process that offers high precision and quality. It is ideal for manufacturing complex shapes and geometries, and can be used for a wide range of materials and applications. If you are looking for a cutting-edge solution that can help take your production to the next level, laser beam cutting is the way to go. Contact us today to learn more about our laser cutting systems and services.